AC contactor wiring diagrams are essential for understanding electrical connections in systems using AC contactors․ They visually represent the flow of electricity, ensuring safe and efficient installations․

What is an AC Contactor?

An AC contactor is an electrically controlled device used to switch electrical circuits on and off․ It operates by using a low-voltage electrical control signal to open or close high-voltage electrical connections․ AC contactors are widely used in air conditioning systems, industrial machinery, and power distribution systems․ They consist of a coil, contacts, and terminals․ When the coil is energized, it creates a magnetic field that moves the contacts, either connecting or disconnecting the circuit․ AC contactors are essential for controlling and protecting electrical loads, ensuring safe and efficient operation of equipment․ They are durable and designed to handle frequent switching cycles, making them a critical component in many electrical systems․

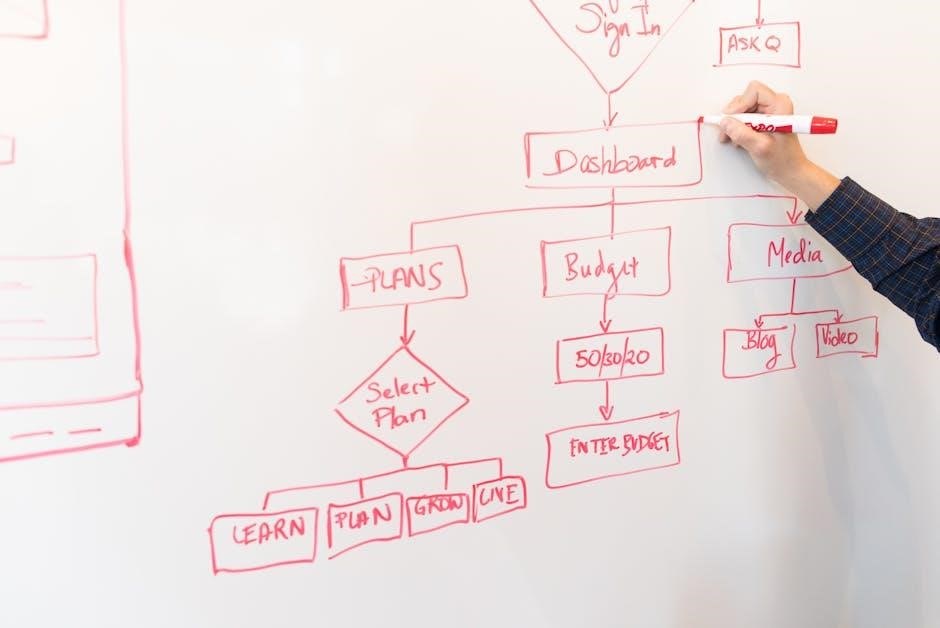

Importance of Wiring Diagrams

Wiring diagrams are crucial for ensuring the safe and efficient installation, operation, and maintenance of electrical systems․ They provide a visual representation of the electrical connections, making it easier to understand how components like AC contactors function within a circuit․ These diagrams help technicians identify potential issues, troubleshoot faults, and perform repairs accurately․ By following a wiring diagram, users can avoid dangerous electrical mismatches and ensure compliance with safety standards․ Additionally, diagrams simplify the process of upgrading or modifying systems, reducing the risk of errors; They are essential for both professionals and DIY enthusiasts, serving as a clear guide to achieving reliable and efficient electrical connections․

Types of AC Contactors

AC contactors come in various types, including single-pole and double-pole models․ Each type is designed for specific applications, ensuring reliable control of electrical circuits and loads;

Single-Pole Contactor

A single-pole contactor is a fundamental component in electrical systems, designed to control the flow of electrical current through a single circuit․ It features a simple design with one moving contact and one fixed contact, ensuring reliable switching operations․ Commonly used in residential and light commercial applications, single-pole contactors are ideal for managing single-phase power supplies․ They are often utilized in air conditioning units, where they control the compressor and fan motors․ The wiring process involves connecting the coil to a control circuit, while the load terminals handle the high current․ Proper installation ensures safe and efficient operation, making single-pole contactors a versatile and essential part of many electrical systems․

Double-Pole Contactor

A double-pole contactor is an electrical switching device designed to control two circuits simultaneously․ It features two pairs of contacts (NO and NC), allowing it to handle higher power requirements․ This type of contactor is commonly used in three-phase systems and applications requiring precise control over multiple circuits․ The double-pole design ensures that both circuits are energized or de-energized together, maintaining system balance and preventing phase mismatches․

When wiring a double-pole contactor, the coil is connected to a control circuit, while the load terminals manage the high-current flow․ Proper installation ensures safe and efficient operation, making double-pole contactors ideal for industrial and commercial applications where reliable power control is essential․

Applications of AC Contactors

AC contactors are widely used in residential and commercial settings to control electrical systems efficiently․ They are essential for managing high-power devices like air conditioning units, HVAC systems, and industrial machinery․

In residential settings, AC contactors ensure reliable operation of home appliances․ In commercial environments, they handle complex electrical demands, maintaining operational consistency and safety․

Residential Use

In residential settings, AC contactors play a crucial role in managing electrical systems for air conditioning units, HVAC systems, and other high-power appliances․ They ensure reliable control of power supply, enabling smooth operation of these devices․

AC contactors are often used to connect and disconnect electrical circuits safely․ In homes, they are integral to air conditioning systems, allowing thermostats to control compressors and fans efficiently․ Proper wiring, as shown in AC contactor wiring diagrams, is essential for safe and effective installation․

Commercial Use

In commercial environments, AC contactors are widely used for controlling high-power electrical systems, including industrial machinery, large HVAC systems, and lighting circuits․ They provide durable and reliable switching solutions․

These contactors are essential for managing heavy electrical loads in factories, offices, and retail spaces․ AC contactor wiring diagrams are crucial for ensuring proper installation and maintenance, helping to prevent downtime and electrical hazards․

Reading and Interpreting Wiring Diagrams

AC contactor wiring diagrams provide a visual guide to understanding electrical circuits․ They use standardized symbols to represent components, ensuring precise connections and safe installations․

Understanding Symbols

Mastering the symbols in AC contactor wiring diagrams is crucial for accurate interpretations․ Common symbols include circles for contacts, coils represented by zigzag lines, and rectangles for contactors․ These symbols are standardized to ensure universal understanding; Each symbol corresponds to a specific component, making it easier to identify parts like capacitors, relays, and fuses․ By recognizing these symbols, technicians can trace circuits efficiently, ensuring proper connections and avoiding errors․ Proper symbol interpretation is essential for safe and effective troubleshooting and installation of AC contactor systems․

Identifying Components

In AC contactor wiring diagrams, identifying components is essential for proper system operation․ Key components include the coil, which activates the contactor, and the contacts (NO and NC), which control the electrical flow․ Other elements like capacitors, relays, and fuses are also represented․ Each component is labeled with distinct symbols, making it easier to trace connections․ For example, the coil is often shown as a zigzag line, while contacts are depicted as circles or rectangles․ Understanding these elements ensures accurate installations and troubleshooting․ Familiarity with component representations in diagrams is critical for diagnosing issues and maintaining electrical systems effectively․

Safety Considerations

Always disconnect power before working with AC contactors to avoid electrical shocks or injuries․ Use insulated tools and ensure compliance with local safety standards․

Precautions

When handling AC contactors, ensure all power sources are disconnected to prevent electrical shocks․ Use insulated tools to avoid accidental contact with live circuits․ Always refer to the manufacturer’s wiring diagram for specific instructions․ Verify the compatibility of the contactor with the system’s voltage and current ratings․ Wear appropriate personal protective equipment, including gloves and safety glasses․ Never attempt to modify the contactor or its wiring without proper training․ Ensure the installation area is well-ventilated and free from flammable materials․ Regularly inspect the contactor and its connections for signs of wear or damage․ Follow local electrical codes and safety standards to ensure compliance․ Proper grounding of the system is crucial to prevent potential hazards․ By adhering to these precautions, you can safely and effectively work with AC contactors and their wiring diagrams․

Best Practices

Adhering to best practices when working with AC contactors ensures reliable and safe electrical systems․ Always use the provided wiring diagram specific to your contactor model․ Double-check connections to avoid miswiring, which can lead to system malfunctions․ Use high-quality, appropriately rated wires and connectors to minimize resistance and heat buildup․ Mount the contactor securely to prevent vibration-induced damage․ Regularly test and inspect the contactor and its wiring for wear or damage․ Label all wires clearly to facilitate future maintenance and troubleshooting․ Ensure the contactor is installed in a well-ventilated area to prevent overheating․ Follow manufacturer guidelines for torque specifications when tightening terminals․ Keep a copy of the wiring diagram on site for quick reference․ By following these best practices, you can ensure optimal performance and longevity of your AC contactor system․

Troubleshooting Common Issues

AC contactor wiring diagrams help identify common issues like faulty wiring or misaligned contacts․ Regularly inspect connections and ensure proper alignment to maintain system reliability and safety․

Common Issues

AC contactor wiring diagrams often highlight issues such as incorrect wiring, leading to failed contactor operation․ Other common problems include overloaded circuits, misaligned contacts, and power supply inconsistencies․ Faulty terminals or worn-out components can also disrupt functionality․ Additionally, improper installation or poor maintenance may cause intermittent operation or complete system shutdowns․ Using the correct wiring diagram helps identify these issues, ensuring proper troubleshooting and repair․ Regular inspections and adherence to safety protocols are essential to prevent such problems and maintain system efficiency․

Solutions

AC contactor wiring issues can be resolved by following proper installation and maintenance guidelines․ Start by ensuring all connections match the wiring diagram, verifying terminal connections, and checking for wear or damage․ Replace faulty components like coils or contacts to restore functionality․ Properly sizing the contactor for the load prevents overload issues, while ensuring the control voltage matches the coil rating avoids misoperation․ Regularly inspecting and cleaning contacts can prevent failures․ Using high-quality components and following manufacturer instructions minimizes errors․ For complex problems, consulting a licensed electrician is recommended․ Always refer to the latest wiring diagram PDF for specific configurations to ensure safety and efficiency in troubleshooting and repair․

Be First to Comment