Welcome to the Davey Pump Repair Manual‚ a comprehensive guide designed for technicians and homeowners. This manual provides detailed troubleshooting‚ repair‚ and maintenance instructions for Davey pumps‚ ensuring optimal performance and longevity. By following the step-by-step procedures and safety guidelines‚ users can effectively diagnose and resolve common issues‚ extending the lifespan of their pump system.

Overview of the Davey Pump and Its Importance

The Davey Pump is a reliable and durable water pumping solution widely used in residential‚ agricultural‚ and industrial settings. Known for its efficiency and versatility‚ it plays a crucial role in water supply systems‚ irrigation‚ and pressure boosting. Its robust design ensures consistent performance under various conditions‚ making it a trusted choice for users worldwide. Proper maintenance and repair are essential to uphold its functionality and extend its lifespan‚ highlighting the importance of this repair manual.

Purpose and Scope of the Repair Manual

This repair manual serves as a detailed guide for diagnosing‚ maintaining‚ and repairing Davey pumps. It provides step-by-step instructions‚ troubleshooting tips‚ and essential safety precautions to ensure effective repairs. The manual covers a wide range of topics‚ from basic maintenance to complex overhauls‚ catering to both professionals and DIY enthusiasts. By following the guidelines outlined‚ users can restore their pump’s performance‚ ensuring reliability and longevity. This comprehensive resource is indispensable for anyone seeking to understand and service Davey pumps efficiently.

Key Features of the Davey Pump Repair Manual

The manual offers a detailed troubleshooting guide‚ comprehensive diagrams‚ and step-by-step repair instructions. It covers various pump models and provides essential maintenance tips for optimal performance.

Comprehensive Troubleshooting Guide

The Davey Pump Repair Manual includes a detailed troubleshooting section to identify common issues. It covers symptoms like low pressure‚ excessive noise‚ and leakage. The guide provides systematic steps to diagnose problems‚ from checking power supply to inspecting internal components. Users can quickly pinpoint faults and apply appropriate solutions‚ ensuring minimal downtime and efficient repairs. This section is invaluable for both professionals and DIY enthusiasts‚ offering clear‚ actionable advice for resolving pump-related challenges effectively.

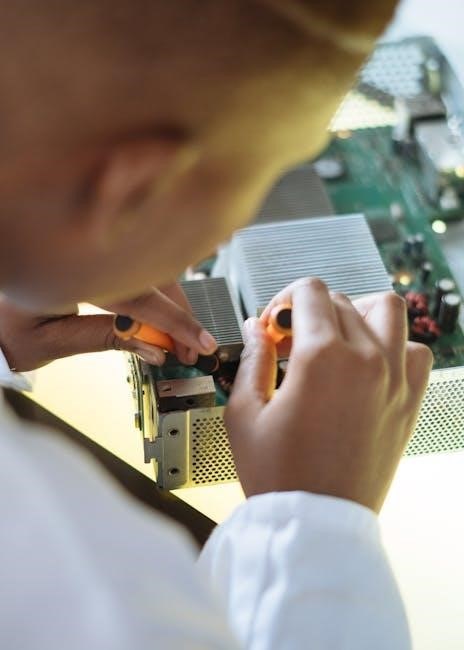

Detailed Diagrams and Illustrations

The manual features detailed diagrams and illustrations to guide users through complex repair procedures. These visuals simplify the identification of components‚ such as valves‚ motors‚ and pipes‚ ensuring accurate disassembly and reassembly. The diagrams also highlight proper installation techniques and safety precautions‚ like using PVC or polythene pipes for optimal performance. By referencing these visuals‚ users can better understand the pump’s internal mechanics and perform repairs with confidence‚ minimizing errors and ensuring long-term reliability.

Step-by-Step Repair Instructions

The manual provides clear‚ methodical repair instructions for Davey pumps‚ ensuring repairs are executed safely and effectively. Each procedure is broken down into logical steps‚ from isolating the system to testing post-repair functionality. Instructions emphasize relieving internal pressure before disassembly and using appropriate tools like PVC or polythene pipes for optimal performance. Whether addressing electrical issues or mechanical faults‚ the guide offers precise directions‚ enabling both professionals and homeowners to restore their pump system efficiently and reliably.

Essential Tools and Safety Precautions

Essential tools include wrenches‚ pliers‚ and pressure gauges. Always relieve internal pressure before disassembly to avoid accidents. Use PVC or polythene pipes for optimal performance and safety;

Recommended Tools for Repair

Essential tools for repairing a Davey pump include adjustable wrenches‚ needle-nose pliers‚ screwdrivers‚ and a multimeter for electrical diagnostics. A pressure gauge is crucial for measuring system pressure‚ while Teflon tape ensures leak-proof connections. Use a set of metric and imperial sockets for bolts and nuts. Additionally‚ keep a pair of insulated gloves and safety goggles on hand for protection. High-quality tools are vital for ensuring accurate repairs and maintaining the pump’s reliability over time. Always refer to the manual for specific tool recommendations.

Safety Guidelines for Handling the Pump

Always disconnect the power supply and relieve internal pressure before starting repairs. Wear protective gloves and safety goggles to prevent injury from sharp edges or debris. Ensure the pump is on a stable‚ flat surface to avoid accidental tipping. Never disassemble the pump while it is under pressure‚ as this can cause serious harm. Use only approved tools and materials‚ such as PVC or polythene pipes‚ to maintain system integrity and safety. Keep loose clothing tied back and avoid overheated components to prevent burns.

Troubleshooting Common Issues

Identify faults by checking power supply‚ performing isolation tests‚ and inspecting control switches. Common problems include faulty switches‚ low water pressure‚ or blocked valves‚ requiring immediate attention to ensure proper pump function and prevent further damage.

Identifying Faults in the Pump System

Identifying faults in the Davey pump system begins with a thorough inspection. Check the power supply and ensure all connections are secure. Perform an isolation test to determine if the issue lies within the pump or external components. Inspect the control switch for any signs of damage or malfunction. Look for indicators such as low water pressure‚ unusual noises‚ or leaks. These steps help pinpoint the root cause‚ ensuring effective troubleshooting and repair. Regular inspections can prevent major breakdowns and extend the pump’s lifespan.

Common Problems and Their Solutions

Common issues with Davey pumps include low water pressure‚ faulty control switches‚ and power supply problems. To address these‚ check the pump’s connections and ensure proper installation. For low pressure‚ inspect the suction line for blockages. Faulty switches may require replacement. Power issues can be resolved by verifying electrical connections. Regular maintenance‚ such as cleaning filters‚ can prevent these problems. Always refer to the manual for specific solutions to ensure optimal performance and extend the pump’s lifespan.

The Repair Process

The repair process involves systematic steps‚ starting with disassembly and inspection to identify faults. Replace worn or damaged parts with genuine components. Reassemble carefully‚ ensuring alignment and tightness. Test the pump post-repair to confirm proper function and reliability.

Disassembly and Inspection

Begin by gathering essential tools and ensuring the pump is disconnected from power. Relieve internal pressure before disassembling components. Document each step for reassembly accuracy. Inspect internal parts for wear‚ corrosion‚ or damage. Clean components thoroughly to assess condition. Identify areas requiring replacement or adjustment. Use manufacturer-approved tools to avoid further damage. This process ensures a thorough understanding of the pump’s condition‚ aiding in effective repairs and maintaining its performance. Always follow safety guidelines during disassembly.

Replacing Worn or Damaged Parts

Once disassembled‚ identify worn or damaged components by comparing them to the manual’s specifications. Replace seals‚ gaskets‚ or impellers using genuine Davey parts for optimal performance. Lubricate moving parts as directed and align components precisely during reinstallation. Tighten bolts gradually to avoid uneven stress. After replacing parts‚ conduct a leak test and ensure all tolerances are within manufacturer guidelines. Proper replacement ensures reliable operation and prevents future damage. Always refer to the manual for specific part numbers and torque specifications.

Reassembly and Testing

Reassembly requires careful alignment of all components to ensure proper fit and function. Tighten bolts gradually‚ following the manual’s torque specifications. After reassembling‚ perform a thorough leak test by operating the pump at low pressure. Check for any signs of leakage or unusual noise. Once confirmed functional‚ gradually increase pressure to recommended levels. Test the pump under load to ensure optimal performance. Record test results for future reference and adjust settings as needed for consistent operation.

Maintenance Tips for Prolonged Pump Life

Regular inspection‚ cleaning‚ and replacement of worn parts ensure optimal performance. Follow recommended schedules and guidelines to maintain efficiency and extend the pump’s operational lifespan effectively.

Regular Maintenance Schedule

A well-structured maintenance schedule is crucial for ensuring the longevity and efficiency of your Davey pump. Begin with monthly inspections to check for signs of wear‚ clean filters‚ and ensure all connections are secure. Every three months‚ inspect the pump’s electrical components and lubricate moving parts as recommended. Annually‚ perform a thorough inspection of the entire system‚ including pipes and valves‚ and replace any worn or damaged components. Adhering to this schedule will help prevent unexpected breakdowns and maintain optimal performance over time.

Best Practices for Pump Care

Proper care of your Davey pump involves regular inspections‚ cleaning‚ and adherence to manufacturer guidelines. Always ensure the pump and surrounding area are free from debris. Lubricate moving parts periodically to reduce friction and wear. Avoid overloading the system‚ as this can lead to premature damage. Store spare parts in a dry‚ cool place to prevent corrosion. Follow the recommended maintenance schedule and keep a record of all servicing for future reference. This proactive approach will ensure reliable operation and extend the pump’s lifespan.

Installation and Configuration

Proper installation and configuration are crucial for optimal pump performance. Locate the pump close to the water source to minimize suction issues. Ensure alignment with the motor and piping system is accurate. Use recommended materials‚ like PVC or polythene pipes‚ for durability. Configure settings according to the manual to match your specific application needs. Always follow safety guidelines and manufacturer instructions to avoid operational issues and ensure longevity of the pump system.

Proper Installation Techniques

Proper installation techniques ensure efficient and safe operation. Position the pump close to the water source to minimize suction issues. Use PVC or polythene pipes for durability. Ensure the pump is level and aligned with the motor. Install isolation valves to facilitate maintenance. Follow manufacturer guidelines for piping and electrical connections. Relieve internal pressure before disassembling any components. Ensure all fittings are secure to prevent leaks. Proper installation techniques are essential for optimal performance and longevity of the Davey pump system.

Configuring the Pump for Optimal Performance

Configuring the Davey pump involves setting the correct pressure and flow rates for your system. Adjust the pressure switch to match your water supply needs. Ensure proper alignment of the pump and motor for efficient operation. Use the recommended pipe size and material to minimize resistance. Configure the control settings according to the manual for automatic or manual operation. Regularly test the system to ensure optimal performance and make adjustments as needed for reliable functionality and longevity.

Common Mistakes to Avoid

Avoid neglecting pressure relief before disassembly and using incorrect pipe materials. Ignoring safety guidelines and improper reassembly can lead to system failure and reduced pump lifespan.

Typical Errors in Repair and Maintenance

Common mistakes include failing to relieve internal pressure before disassembly‚ using incorrect materials‚ and improper reassembly. Overlooking safety guidelines can lead to system damage or failure. Additionally‚ ignoring regular maintenance schedules and using incompatible replacement parts are frequent errors. These oversights can result in reduced pump efficiency and lifespan. Always follow the manual’s instructions precisely to avoid such issues and ensure optimal performance.

How to Ensure Long-Term Reliability

For long-term reliability‚ strictly adhere to the maintenance schedule outlined in the Davey Pump Repair Manual. Regularly inspect and replace worn parts‚ and use genuine components to prevent system compromise. Proper installation and configuration are crucial‚ as outlined in the manual. Always follow safety guidelines to avoid damage during repairs. Consistent upkeep and adherence to best practices ensure the pump operates efficiently and reliably over its lifespan.

This manual provides essential guidance for maintaining and repairing Davey pumps. By following the outlined procedures and best practices‚ users can ensure optimal performance and longevity of their pump system.

Summarizing Key Repair and Maintenance Strategies

Regular maintenance is crucial for extending the lifespan of your Davey pump. This includes inspecting and replacing worn parts‚ ensuring proper installation‚ and following safety guidelines. Troubleshooting common issues like power supply problems or faulty switches can prevent major breakdowns. Referencing the manual’s detailed diagrams and step-by-step instructions ensures repairs are done correctly. By adhering to these strategies‚ users can maintain optimal performance and reliability of their pump system‚ minimizing downtime and extending its operational life.

Encouragement for Proper Manual Usage

Properly using the Davey Pump Repair Manual ensures safety‚ efficiency‚ and optimal pump performance. By following the guidelines‚ users can avoid common mistakes and extend the pump’s lifespan. Regular maintenance and timely repairs‚ as outlined‚ prevent major breakdowns and reduce costs. Encourage all operators to thoroughly review and adhere to the manual’s instructions‚ fostering a culture of compliance and reliability. This approach guarantees long-term functionality and peace of mind for years to come.

Be First to Comment